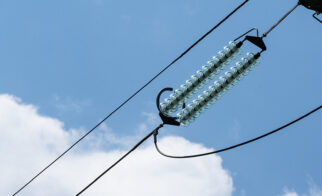

RTE pioneered a circular approach to grid renewal by recycling aluminium from decommissioned conductors into new high-performance lines. This innovation reduces carbon emissions, strengthens supply chain resilience, and proves that recycled materials can meet technical standards, setting a model for sustainable and resource-efficient energy infrastructure.

Highlights

01

Recycled 40 kilometres of ageing conductors, producing high-performance lines with identical strength and conductivity.

02

Used only 5% of the energy required for virgin aluminium production, cutting 7 tons of CO₂ per tonne.

03

Pilot completed in 2023 across five French sites, proving the feasibility of large-scale aluminium circularity.

Main Information

Facing rising global demand for aluminium and the urgent need to cut emissions, RTE launched a first-of-its-kind circular project to recycle material from its decommissioned overhead lines. Instead of relying on energy-intensive primary aluminium, the French transmission system operator tested whether recovered conductors could be remade into new, high-performance lines.

The goal was to reduce environmental impact, secure strategic resources, and demonstrate that circular solutions can meet strict technical standards. Working with French partners including MTB Recycling, Trimet and Nexans, RTE recovered, remelted and re-manufactured 40 kilometres of ageing lines into new conductors that matched the mechanical strength and electrical conductivity of conventional ones.

The process used only 5% of the energy needed for primary production and cut seven tonnes of CO₂ per tonne of aluminium. The recycled conductors were successfully installed on the national grid in 2023, confirming industrial feasibility. RTE now plans to expand this approach to underground copper cables and transformers, creating a sustainable, local supply chain for critical materials and setting a European benchmark for circular energy infrastructure.

other practices