TenneT successfully completed emission-free drilling for a high-voltage grid enforcement project in a sensitive area for nature and people using hydrogen. With this hydrogen drilling pilot, the only nitrogen emissions emitted were those from the trucks that transport the hydrogen to the construction site while disturbances from noise and smell were also minimised.

Highlights

01

This pilot was the first time a drilling operation for a high-voltage cable was performed using hydrogen.

02

Benefits include the prevention of harmful emissions, including nitrogren and carbon dioxide, and minimisation of disturbances (noise and smell).

03

Potential for broad applicability across different industries and geographies, contributing learnings for advancing zero emission construction works.

Main Information

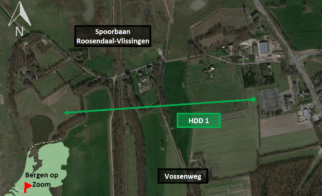

Innovations for emissionless heavy construction equipment are needed by the whole construction sector, including electricity grid operators. In addition, nitrogen emissions from regular drilling equipment can prevent high-voltage cable installation and enhancement in areas near Natura2000 sites. TenneT has addressed these two issues by successfully testing a new method for hydrogen-powered drilling for a high-voltage cable next to a nitrogen sensitive nature area. This was the first time a drilling operation for a high-voltage cable was performed using hydrogen and is therefore an important step in the process towards zero emission construction works.

Over the 10 days of drilling activities, TenneT used hydrogen originating from an electrolyzer that is powered by wind and solar energy. The trucks involved in the project were also powered by ‘HVO100,’ an almost entirely CO2-free fuel. With this method, the only nitrogen emissions that remain are those from the trucks that transport the hydrogen to the construction site.

This method prevented harmful emissions, including nitrogen and carbon dioxide, and minimised disturbances (noise and smell) for people who work on or live near the construction site compared to the traditional method with a diesel generator. In total, 27750 kg of carbon dioxide emissions and 125kg of nitrogen emissions were saved. Though further innovation is needed and it is not applicable in all situations, the hydrogen drilling pilot can be easily scaled up and provided valuable learnings for the whole construction sector.

other practices